Threaded bushings come in hex head, reducing, and screwed types. Their sizes go from 1/8" NB up to 4" NB. These bushings have threads that are straight or tapered. The type of thread changes how well they stop leaks and handle pressure. Tapered threads can hold higher pressure. Straight threads need extra seals to work well. Bushings are made from stainless steel, carbon steel, or nickel alloys. Each material fits different jobs and places. Picking the right threaded bushing depends on what you need it for. Plumbing, electrical, or mechanical systems need the right size, material, and thread type. This keeps things safe and makes sure parts fit together.

Attribute | Details |

Size Range | From 1/8" NB to 4" NB |

Types | Threaded (S/W), Screwed (SCRD) with thread standards: NPT, BSP, BSPT |

Forms | Threaded Bushing, Hex Head Bushing, Reducing Bushing |

Pressure Classes | 3000 LBS, 6000 LBS, 9000 LBS |

Materials | Carbon Steel, Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Cupro Nickel |

Key Takeaways

Threaded bushings have different types. These include hex, reducing, flanged, insert, and specialty. Each type is made for a certain job. Each type works with different pressure levels.

Picking the right thread type is important. You can choose NPT, NPTF, UNF, UNC, metric, or imperial. The right thread type helps stop leaks. It also makes sure the fit is strong.

Always match the bushing size to your pipes. Match the thread type to your fittings too. This helps you avoid leaks. It also stops fitting problems.

Choose the right material for your bushings. You can pick stainless steel, PVC, brass, or copper nickel. Pick based on where you use it. Also think about how much pressure it needs to handle.

Install bushings the right way. Clean the threads first. Use sealants if you need them. Do not tighten too much. This keeps connections safe. It also helps stop leaks.

Threaded Bushing Types

Hex Bushings

Hex bushings have a head shaped like a hexagon. This shape lets you use a wrench to tighten them. They join pipes or fittings with different sizes. You often see hex bushings in plumbing and machines. They can handle strong pressure and stop leaks if put in right. Most hex bushings are made from stainless steel, carbon steel, or copper nickel. Their pressure ratings go from 2000 to 9000 class. The hex head makes it easy for workers to put in or take out bushings fast.

Reducing Bushings

Reducing bushings make a pipe opening smaller. They let a big fitting join with a small one. These bushings work well in water pipes and gas lines. Reducing bushings can handle many pressure classes like 3000, 6000, and 9000. Makers use stainless steel, PVC, and alloy steel to make them. The bushings fit into threaded pipe fittings and help control flow between pipe sizes.

Tip: Always look at the pressure rating before picking a reducing bushing for high-pressure jobs.

Flanged Bushings

Flanged bushings have a wide rim called a flange. The flange gives extra support and helps seal the joint. These bushings work best where shaking or movement might loosen things. Flanged bushings are found in machines and some plumbing systems. They are made from stainless steel and cupro nickel. Pressure ratings for flanged bushings can go up to 6000 class. The flange keeps the bushing steady and stops leaks.

Insert Bushings

Insert bushings connect parts in electrical systems. They link wells and elbows in underground or pad-mounted gear. These bushings meet rules like IEEE Std 386, EN-50180, EN50181, and IEC 60502. Insert bushings are important in separable connectors. Voltage class ratings go from 15 kV to 38 kV. Their main job is in medium voltage electrical fittings.

Insert bushings join wells and elbows in underground electrical gear.

They follow strict rules for safety and reliability.

Voltage ratings show they work in medium voltage systems.

Specialty Bushings

Specialty bushings include insulated, corrosion-resistant, and template bushings. Insulated bushings protect against electrical problems. Corrosion-resistant bushings last longer in tough places. Template bushings help guide tools when putting them in. Specialty bushings use duplex steel, nickel alloys, and PVC. Pressure ratings change by type and material. These bushings fit into special fittings for unique jobs.

Bushing Type | Common Materials | Pressure Class (LBS) | Typical Application |

Hex | Stainless, Carbon Steel | 2000-9000 | Plumbing, Mechanical |

Reducing | Stainless, PVC, Alloy | 3000-9000 | Water, Gas |

Flanged | Stainless, Cupro Nickel | Up to 6000 | Mechanical, Plumbing |

Insert | Copper, Epoxy | N/A (Voltage Rated) | Electrical (Medium Voltage) |

Specialty | Duplex, Nickel, PVC | Varies | Electrical, Corrosive Environments |

Different Types of Threads

Threaded bushings have different thread shapes. Each shape changes how well it seals and how strong it is. Some threads work better in certain places. Knowing about thread types helps you pick the right bushing for each job.

NPT vs. NPTF

NPT and NPTF are two main pipe threads in North America. Both have a tapered shape. This means the thread gets smaller as it goes along. The taper helps seal the joint and makes it stronger.

NPT means National Pipe Taper. It is a common pipe thread. NPT threads need sealant like Teflon tape. The sealant fills small spaces and stops leaks. Without sealant, water or gas can leak out. NPT bushings are good for plumbing and gas lines. They work when a perfect seal is not needed.

NPTF means National Pipe Taper Fuel. This thread is also tapered but fits tighter. The threads press together more closely. This makes a seal without extra sealant. NPTF bushings stop leaks better. They are used in fuel, oil, and hydraulic systems. These places cannot have leaks.

Feature | NPT | NPTF |

Thread Profile | General-purpose taper | Modified taper for fuel and oil |

Sealing Mechanism | Needs sealant (e.g., Teflon tape) | Mechanical seal, no sealant needed |

Leak Resistance | Depends on sealant | High, due to interference fit |

Strength and Fit | Wider tolerance, uses sealant | Tighter fit, stronger under pressure |

Common Applications | Plumbing, gas lines | Fuel, oil, hydraulic systems |

Compatibility | Not fully compatible with NPTF | Not fully compatible with NPT |

Note: If you mix NPT and NPTF threads, leaks can happen. Always use the right thread type for your job.

UNF vs. UNC

UNF and UNC are other thread types. They are not for pipes. You see them in machines and fasteners. UNF means Unified National Fine. UNC means Unified National Coarse.

UNF threads are close together. This makes a strong hold. They do not loosen easily from shaking. UNF bushings are used in cars and machines. They are good when you need a tight fit.

UNC threads are farther apart. They are easier to put together. They do not cross-thread as much. UNC bushings are used in building and general work. They are good for rough jobs and quick installs.

UNF: Fine threads, strong grip, best for places with lots of shaking.

UNC: Coarse threads, easy to use, good for most jobs.

Metric vs. Imperial

Metric and imperial threads use different ways to measure. Metric threads use millimeters. Imperial threads use inches. Both can be parallel or tapered.

Metric threads are common in Europe and Asia. The first number is the diameter in millimeters. The second is the space between threads. For example, M12 x 1.75 means 12 mm wide and 1.75 mm between threads. Most metric bushings use parallel threads. These need a gasket or O-ring to seal.

Imperial threads are used in the United States and Canada. They use inches for size and threads per inch for pitch. For example, 1/2"-14 NPT means 1/2 inch wide and 14 threads per inch. Many imperial bushings use tapered threads. These can seal without extra gaskets.

Tip: Always check if you need metric or imperial sizes before picking a bushing. Mixing them can cause leaks or break parts.

Key Points on Thread Forms

Tapered threads, like NPT and NPTF, seal by wedging together. They are good for high-pressure jobs.

Parallel threads, found in many metric bushings, need extra seals to stop leaks.

The choice between parallel and tapered threads depends on the job, pressure, and if you need to stop leaks.

Picking the right thread shape makes sure the bushing fits well. It also helps stop leaks and makes the bushing last longer. Knowing thread types helps you avoid leaks and problems in plumbing, electrical, and mechanical work.

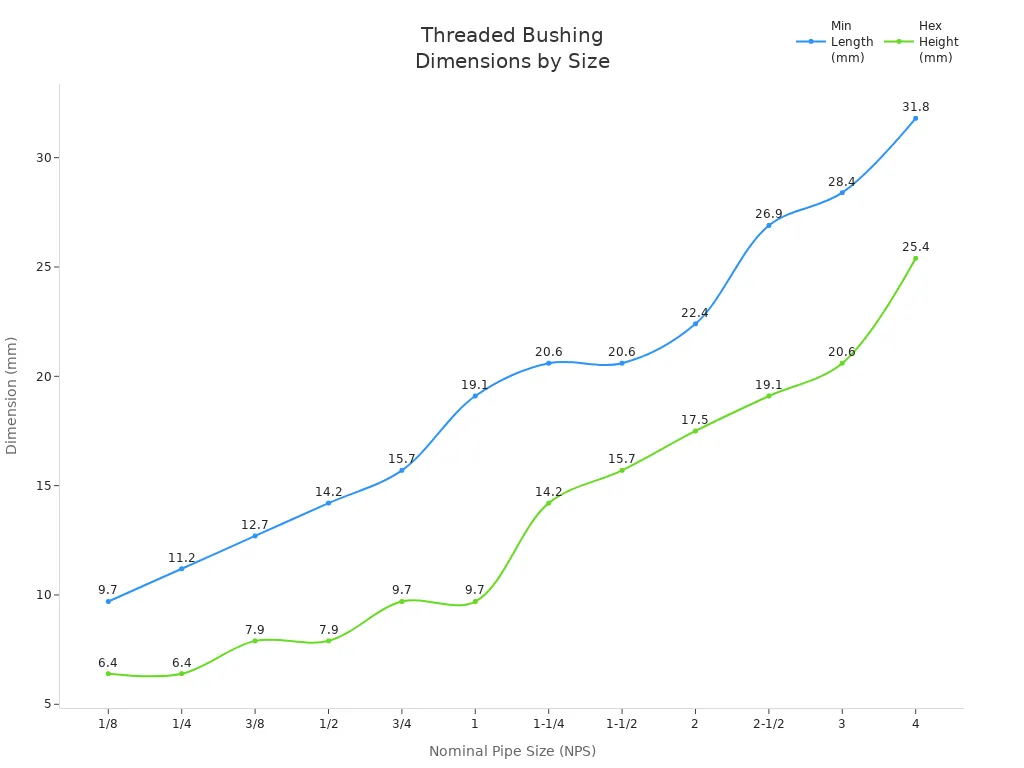

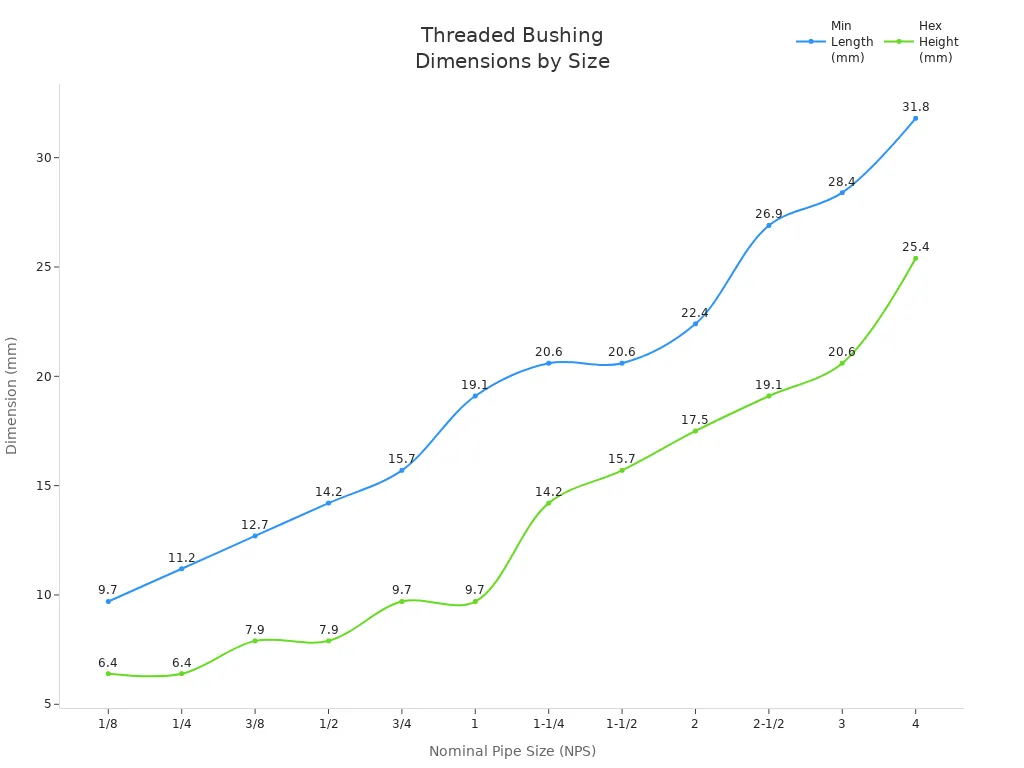

Threaded Bushing Sizes

Standard Pipe Sizes

Threaded bushings come in many standard pipe sizes. These sizes match the most common pipe and tube diameters used in plumbing and mechanical systems. Pipe sizes often range from 1/8 inch up to 4 inches. Each size connects with specific fittings, so users must check both the inside and outside diameters. Pipe sizing follows set increments, which helps workers find the right match for their project. When choosing a threaded bushing, always check the thread size to make sure it fits with the pipe and other fittings in the system.

Common Diameters (M12, M16, M20)

Metric thread sizes are popular in many parts of the world, especially in Europe and Asia. The most common metric diameters for threaded bushings include M12, M16, and M20. These sizes refer to the nominal outside diameter in millimeters. The thread size also includes the pitch, which is the distance between threads. For example, M12 has a 1.75 mm pitch, while M16 and M20 usually have a 1.5 mm pitch. These metric bushings work well in mechanical and industrial fittings, such as machinery and pneumatic systems.

Metric Thread Size | Nominal Diameter (mm) | Common Pitch (mm) | Typical Use |

M12 | 12 | 1.75 | Machinery, pneumatic fittings |

M16 | 16 | 1.5 | Industrial equipment, pipe fittings |

M20 | 20 | 1.5 | Heavy-duty fittings, mechanical |

Measuring and Identifying Size

Accurate measurement ensures the right fit for every threaded bushing. Workers use several tools and steps to check thread size and match fittings:

Use a ruler to measure the thread pitch. Count the number of thread peaks over a 1-inch span for imperial threads or measure the distance between threads for metric threads.

Match the thread with a known sample, thread chart, or nut/bolt tester to identify both size and pitch.

Use a thread angle gauge to check the angle of the threads.

Clean the threads before measuring to remove any debris.

Double-check measurements for accuracy.

Use good lighting to see fine thread details.

Handle measuring tools with care to keep them precise.

Tip: Always check both the thread size and the type of fittings before making a final selection. This step helps prevent leaks and ensures a secure connection.

Types of Pipe Thread Fittings

Application Recommendations

Different types of pipe thread fittings work best in certain jobs. NPT fittings use tapered threads. These threads create a tight seal when tightened. NPT fittings stop leaks well. People use them in plumbing for water, gas, and fire protection. NPT fittings also work in mechanical systems that need leak-tight seals. NPSM fittings have straight threads. These fittings do not seal as tightly. NPSM fittings fit well in electrical systems, lighting, and low-pressure machines. They work where sealing is not the main goal.

Thread Type | Thread Design | Sealing Capability | Suitable Applications |

NPT | Tapered | High, watertight | Plumbing, gas, fire protection, mechanical |

NPSM | Straight | Low | Electrical, lighting, low-pressure machines |

Tip: Always match the fitting type to the job. Use NPT for plumbing and NPSM for electrical or low-pressure work.

Material Choices

Fittings come in many materials. Stainless steel resists rust and lasts a long time. It works well in wet places and high-pressure jobs. PVC fittings cost less and resist chemicals. People use PVC in water lines and some electrical work. Brass fittings resist corrosion and work in both plumbing and electrical systems. Carbon steel fittings handle high pressure but may rust if wet. Copper nickel fittings work well in salty or marine places.

Stainless steel: Best for high pressure and wet areas.

PVC: Good for water and chemical resistance.

Brass: Works in plumbing and electrical jobs.

Carbon steel: Handles pressure but needs dry spots.

Copper nickel: Best for marine and salty environments.

Installation Tips

Proper installation keeps fittings safe and leak-free. Workers should clean all threads before use. They must check that the fitting matches the pipe size and thread type. For NPT fittings, use Teflon tape or pipe dope to help seal the joint. Tighten fittings with the right tool, but do not over-tighten. Over-tightening can crack the fitting or strip the threads. For NPSM fittings, use them only where sealing is not critical. Always follow the maker’s instructions for each fitting.

Note: Double-check the thread type and size before starting. This step helps avoid leaks and fitting failures.

Comparison Table

Types vs. Sizes

Picking the right bushing type and size keeps pipes safe. Each bushing type fits certain sizes and jobs. The table below shows which bushing types go with common sizes. This helps people choose the best one for their fittings.

Bushing Type | Typical Size Range | Best Use Case | Example Fittings |

Hex Bushing | 1/8" to 4" NB | Plumbing, machines | Pipe to valve fittings |

Reducing Bushing | 1/4" x 1/8" to 4" x 3" | Size changes in pipe systems | Large to small fittings |

Flanged Bushing | 1/2" to 2" NB | Vibration-prone equipment | Pump or motor fittings |

Insert Bushing | M12 to M20, 15-38 kV | Electrical gear | Cable or elbow fittings |

Specialty Bushing | Custom sizes | Special environments | Corrosive area fittings |

Note: Always check both the size and type before you put in bushings.

Materials vs. Applications

The bushing material changes how well it works in different places. Some materials last longer in wet or salty spots. Others are better for high pressure or heat. The table below matches materials to common uses and fittings.

Material | Strengths | Typical Applications | Example Fittings |

Stainless Steel | Rust-resistant, strong | Water, food, outdoor | Plumbing fittings |

Carbon Steel | High pressure, low cost | Industrial, dry areas | Gas line fittings |

PVC | Chemical-proof, light | Water, electrical | Drain or conduit fittings |

Brass | Easy to shape, resists rust | Plumbing, electrical | Valve or tap fittings |

Copper Nickel | Saltwater safe | Marine, ship systems | Boat or dock fittings |

Stainless steel and copper nickel are best for wet or marine places.

PVC and brass work well for water lines and electrical jobs.

Carbon steel is good for high-pressure jobs but needs dry areas.

Tip: Always pick the right material for your fittings to stop leaks and damage.

Each threaded bushing type, thread, and size has its own job. Hex, reducing, flanged, insert, and specialty bushings work for different tasks. NPT, NPTF, UNF, UNC, metric, and imperial threads have different ways to seal and hold strong. Pick the right threaded bushing by matching type, size, and material to your project.

Tip: Always check the pressure rating and make sure the threads match before you put it in.

Quick-Reference Checklist:

Figure out if it is for plumbing, electrical, or mechanical work

Pick the best material for where you will use it

Make sure the thread type and size fit tightly

FAQ

What is a threaded bushing used for?

A threaded bushing joins pipes or fittings of different sizes. It lets you change the thread size or type. People use bushings in plumbing, electrical, and mechanical systems. Bushings help parts fit together tightly.

How do you measure thread size on a bushing?

Use a ruler or thread gauge to measure thread size. For imperial sizes, count threads per inch. For metric sizes, measure the space between threads. Always check the pipe thread type before picking fittings.

What are the most common thread types for bushings?

NPT, BSP, and metric threads are the most common types. NPT is a tapered thread. BSP can be parallel or tapered. These thread types help seal pipes in many jobs.

Can you mix different types of threads in one system?

Mixing parallel and tapered threads can cause leaks or problems. Always match thread type and size when joining bushings and fittings. This keeps things safe and working well.

Which materials work best for different types of pipe thread fittings?

Stainless steel is good for wet or high-pressure places. PVC stands up to chemicals. Brass works in plumbing and electrical jobs. Copper nickel is best for marine areas. Pick the right material for your job and bushing type.